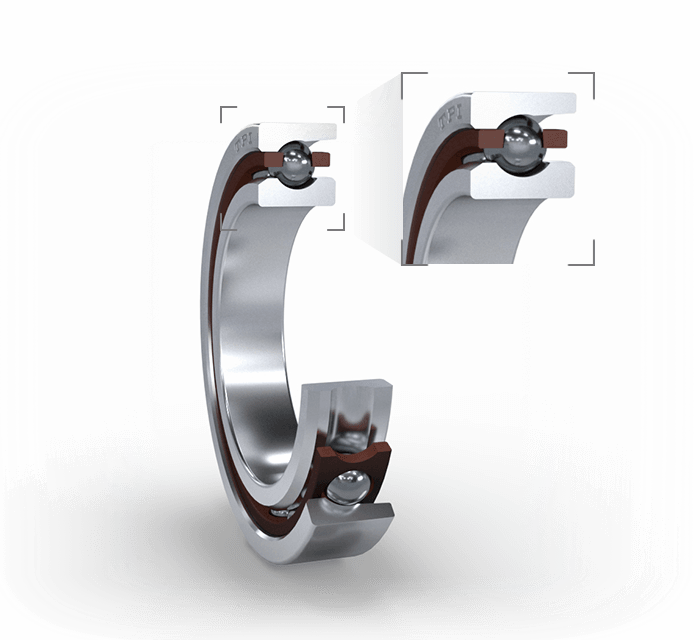

The structure of angular contact ball bearings produces an axial component when a radial or combined load is applied; therefore, two opposed bearings or a multi-bearing arrangement are used.

A preload is often used to increase the rigidity of single-row angular contact ball bearings, particularly in the main spindles of machine tools where high running accuracy is crucial.

Bearings with a contact angle of 30° (A) or 40° (B) typically use pressed steel, molded resin, or machined brass cages, though machined synthetic resin or specialized polyamide resin cages are used for certain applications.

| Series | Pressed Steel Cages | Machined Brass Cages |

|---|---|---|

| 79A5,C | - | 7900-7940 |

| 70A | 7000-7018 | 7019-7040 |

| 70C | - | 7000-7022 |

| 72A,B | 7200-7222 | 7224-7240 |

| 72C | - | 7200-7240 |

| 73A,B | 7300-7320 | 7321-7340 |

ARS Machine, we take pride in delivering cutting-edge solutions with our premium product, Precision Bearing. Designed to meet the highest industry standards, Precision Bearing ensures superior accuracy, smooth operation, and longevity in every application.

Whether used in industrial machinery, automotive components, or heavy equipment, our bearings are meticulously crafted to reduce friction, withstand high loads, and enhance efficiency. Engineered with the latest technology, ARS Machine’s Precision Bearing provides seamless integration into any system, offering unparalleled reliability and performance.

With a focus on quality and durability, ARS Machine is committed to driving excellence in every motion. Trust Precision Bearing for smooth, precise, and consistent operation across all your critical applications.

ACBB, which is the abbreviation of angular contact ball bearings. With different contact angles, the higher axial load can be well taken care now. TPI standard ball bearings are the perfect solution for high runout accuracy applications such as machine tool main spindles.